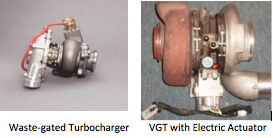

Ever wonder what a VGT is? It stands for Variable Geometry Turbocharger. It might also be called a VNT, which means Variable Nozzle Turbocharger.

There are excellent explanations of VGT designs on the Internet, but our interest here is more upon their maintenance.

First, why are VGTs needed on diesel engines?

The answer is that the former waste-gated designs are too slow for today’s fuel injection systems.

Current common rail fuel injection systems fire as many as five times in one combustion cycle. In order to maintain proper air/fuel ratios, the turbo boost has to be adjusted more rapidly than a pneumatically controlled system can keep up with.

Secondly, the VGT acts as the “traffic cop” which balances air intake pressure with exhaust backpressure required for EGR induction and is constantly “hunting” to maintain the balance.

So what do we need to know about VGTs? Here are some facts about them.

- Boost will fluctuate, depending upon vehicle speed, load and desired EGR flow. Boost is almost instantaneously altered with throttle position changes. Even at steady throttle and constant load the boost might vary with EGR demand.

- Boost can vary day-to-day. Ambient air pressure and temperature are sensed by the ECM so that boost pressures are always optimized for engine operating requirements.

- VGTs will whistle loudly in certain normal engine operating conditions. This condition occurs when the ECM requests more exhaust heat for regeneration of the diesel particulate filter. The whistle might sound like a boost leak but is actually a normal condition.

- VGT sizing must be matched to the engine to prevent over-boost conditions.

- The replacement of a VGT requires reprogramming of the actuator.

In order to protect a VGT from seizing, it is essential that we maintain engine oil cleanliness.

The VGT turns at speeds exceeding 100,000 rpm, so bearing failure is catastrophic. The engine oil both lubricates and cools the bearings.

We want to avoid conditions like these:

We can avoid VGT failure by employing protection procedures.

- First, we match oil changes to engine hours and drive cycles, NOT to mileage.

- Second, we watch for oil pan sludge accumulation and check oil condition when we change oil. Gritty oil will lead to turbo failure.

- Third, we watch for the engine “making oil”. That is, excessive DPF regeneration attempts due to contaminated turbo output pressure sensors or to improper DPG regeneration functions can dilute the oil with fuel.

We need to record OIL LEVELS upon oil changes to protect against dilution.

If we detect sludge build-up, we need to either clean or replace the oil pan and fix the root causes of sludge creation or fuel intrusion.

Taking the proper precautions to prevent VGT failures can save repair bills of thousands of dollars for replacement and calibration of a VGT.