Often referred to as being the same thing, flywheels and flexplates have similarities but are quite different.

1. Flywheels are typically found on vehicles equipped with manual transmissions, while flexplates are used in vehicles with automatic transmissions.

1. Flywheels are typically found on vehicles equipped with manual transmissions, while flexplates are used in vehicles with automatic transmissions.

A manual transmission has a flywheel that is attached to the crankshaft and has a clutch disk in between the pressure plate and flywheel.

When someone presses the clutch, the throwout bearing is pushed in, which forces the pressure plate to stop applying pressure to the clutch disk.

As this happens, it stops receiving power from the engine.

So the gear shifts without damaging the transmission.

Once the operator/driver shifts into a new gear release the clutch pedal then the clutch disk is allowed to start receiving power from the engine once again.

Automatic transmissions eliminate the clutch and grinding.

Basically automating the shifting process so the driver does not have to worry about shifting gears while driving.

A flexplate is mounted to the crankshaft and connects the output from the engine to the input of a torque converter.

Torque converters replace the clutch of a manual transmission.

Allowing the load to be separated from the power source.

They are generally a type of fluid coupling that can multiply torque and is used in transferring rotating power from the prime mover (internal combustion engine or electric motor) to a rotating driven load. The torque converter is located between the flexplate and the transmission.

Flywheels, due to the friction process, are very thick, made of steel and are as heavy as they look.

Their lifecycle can outlast that of the clutch but will need resurfacing before installing a new clutch.

When they need do need replacing, you can typically get away with using an aftermarket replacement.

2. Flexplates are much thinner than a Flywheel

As well as the ring gear it uses to connect with the starter (depending on vehicle and engine size), and are much, much lighter.

This is due to the fluid coupling of the torque converter, which eliminates the grinding of a clutch.

The lighter, thinner metal frame has an ability to flex across its main axis – bending side to side (hence the name Flexplate) – taking up motion in the torque converter as the rotational speeds change.

The metal frame of the flexplate itself will have multiple machine-cut holes within the body of the plate.

One set of holes will look uniform and would be for mounting to the crankshaft.

The other holes are specific to the vehicle, torque converter set-up and potential weight balance of the flexplate.

No matter the car size, small economy size or heavy-duty truck.

If your vehicle has a manual transmission and you have to step on the clutch to shift gears, your vehicle has a flywheel as part of your transmission. If all you have to do is put the shifter in a drive (D) and step on the gas pedal, your vehicle has a flexplate.

3. Repair and replacement cost

If you have problems with your flywheel you probably have to replace them, but what it´s their costs?

The replacement of the flywheel can vary depending on the model and the quality, the prices are about 35$ and 400$. In our shop, we have a variety of flywheels for your comfort.

Those were some important facts about flywheels and flexplates.

Now, can I drive with a cracked flexplate?

Sure you can drive with a broken flexplate but is heavily dangerous.

And the sound of the broken part is terrible if you have a broken flexplate or flywheel you have to go to your mechanic immediately and change the part.

As a purchasing manager for an aftermarket heavy duty replacement truck parts supplier, it is my responsibility to research parts and determine the best parts to add to the inventory.

There are many factors to consider when it comes to adding parts to existing inventory. Age of the part, demand for the part, and quality sourcing are all important. Knowing what parts to start with and the basic information of the part are crucial.

Listening to customers is one of the best ways to figure out what new parts are on the rise. Customers at some point in time will ask the salesforce about a part number that is not in stock or currently available by the company. When this happens, is your salesforce prepared to get the information you will need to make it easier to research the part in question?

Here is a list of questions the salesforce team can ask the customer:

How often do you sell this particular part?

Product demand will help in determining a part. You wouldn’t want to add something that a customer only replaces once a year.

What year is the truck?

Newer trucks will have manufacturer warranties up to 5 years or more. During this time, parts are covered by the warranty, so aftermarket heavy duty replacement truck parts are not needed until the warranty is expired. There is not many older trucks, 35 years or older, that are still roadworthy. Adding new inventory parts for trucks this old would not make sense.

Do you see a wide variety of this type of truck or engine types?

Different geographical areas tend to see more of one type of truck/engine than another. One customer could see more Aftermarket Detroit Diesel engines versus Mack engines.

What is the OEM cost to replace the part?

Aftermarket options need to be of good quality, but also need to be priced as such that it is worth going with the aftermarket part instead of OEM.

Besides polling the salesmen for information, reviewing customer purchase history can be useful. If a customer is purchasing many types of Aftermarket Cummins heavy duty truck replacement parts, you can conclude that they would be open to more Aftermarket Cummins part options.

Let’s say you have a list of some part numbers to research. This list was finalized after speaking with your salesforce and reviewing customer histories, but you are still unsure if you should add this part. Another way to get some information on a part is by doing a ‘Google’ or other web browser search.

Type the part number and part type in the search bar and see what comes up. If the first few pages show multiple listings of this part for retail sale, whether it’s used, remanufactured or new, you more than likely are looking at a part number that is in demand now.

If all you come across in your search are overseas companies looking to sell this part number and no retail listings, you may have an oddball part that isn’t in demand. Either this, or the part is still being covered by manufacturer warranty and will not be in demand for a while. It could be possible that you are using an older part number and should check for alternates to confirm.

Before you add any heavy duty replacement truck parts, be sure you research the parts very carefully, then look for your sourcing options.

You have had your truck for many years now and during routine maintenance of your vehicle, you realize that your exhaust manifold is leaking. Let’s say it’s at a point where you can’t repair the leak, which means you have to replace it.

As you are beginning to inquiry about a new exhaust manifold, your parts supplier asks you if you want ‘Cast Iron’ or ‘Steel’. Would you be able to answer this right away? The OEM manifold that was removed from your truck is more than likely cast iron, so why would you be offered a steel version?

Here is some information that can help you make a decision.

Cast Iron

- The material is inexpensive and fairly easy to work with. OEM manufacturers tend to use cast iron because of this.

- Material is durable and can have a long life span.

- It is heavier than steel and can become brittle and prone to cracking under extreme heat cycles and age.

- Requires special tooling for production, but is easier for mass production.

Steel:

- Steel has different options, mild steel or stainless steel

- Mild steel has a ‘low degree to thermal expansion’ and is an excellent choice for flanges.

- Stainless steel is stronger and more corrosion resistant than mild steel, and also costs more.

- Stainless steel can be prone to expanding during heat cycles, then retracting when cooling. This can rip off the bolts or studs that hold the exhaust system together.

- Can be used to make traditional log style exhaust manifold, but is better suited for custom made tubular exhaust manifolds, without special tooling needed.

Steel exhaust manifolds can reduce heat loss, especially stainless steel versions, which can lead to an added increase in horsepower and performance. You can add a ceramic coating to cast iron exhaust manifolds for a small increase, but not as much as you would gain with steel versions, which can also be given a ceramic coating.

The decision to replace your exhaust manifold and what type of replacement to go with can depend on many factors.

- How long do you plan to keep the truck?

- Do you want increased performance and more horsepower?

- What does your budget look like?

Now that you are more informed, you can choose the best option that fits your needs.

Maintenance of Heavy Duty Trucks

Trucks are a great heavy duty vehicle that has made it possible to transport diverse goods from one place to another. However, they are a big investment, but the maintenance, insurance, and many other factors add to the cost as well.

Because maintaining their parts is an important aspect of keeping trucks on the road. As well made as the parts of a truck may be, they eventually need replacement due to wear.

For freight companies, the key is to replace parts before they break, resulting in having to leave a rig on the side of the road.

Hence, even when routine maintenance is performed, parts will eventually wear out. When this happens, you need to know where to get replacement parts for your trucks.

Although finding parts for used heavy trucks is more challenging than finding parts for a car, there are several good places to source them if you’re willing to do some research.

Thus, a supplier of medium and heavy truck parts will assist with this task, but carriers must choose a parts supplier carefully regarding the fleet services they need.

Below are some diesel engine trucks part that crucial to always take good care of.

Brakes

Knowing how to properly use the brakes will greatly decrease strain on the truck’s system and use far less fuel during even the longest drives.

Many people use the brakes far more than necessary during drives, which is especially true in traffic since they continually accelerate and brake to move forward.

Learning to coast the vehicle can make a significant difference in the amount and regularity of fuel fills.

Flywheels

A truck flywheel may not be familiar to most people, but it is an important part of the truck. The car flywheels are fairly durable one-piece components.

They operate primarily to provide the inertia necessary to carry the engine’s pistons through the unproductive stroke of their cусlе.

Thе teeth that surround the flywheel are used by the starter motor to turn the engine until the engine fires up.

Therefore, they will need replacement if the teeth on the flywheel become worn. There are many signs of the bad car flywheels.

Shock Absorbers

Having good shocks for your used heavy trucks can mean the difference between a controlled drive and one that leaves the driver in a panic.

The shock absorbers affect handling and just about everything else that has a close relationship with the axle, so don’t let them slide.

Make sure the shock absorption is operating by the manufacturer’s recommendations and check them regularly to see if they are іn nеed of replacing.

Proper shock absorbers can cost anything from a few hundred dollars to over a thousand, but take care of thеm, аnd they’ll take care of you.

Thus, Standard rebuild kits which include the following items: cylinder kits (pistons, liners, rings, retainers), main bearings, connecting rod bearings, a head or upper gasket set, rocker cover gasket, and an oil pan gasket.

Commonly needed items also include thermostats, head bolts, camshaft bearings, water pumps, oil pumps, and fuel injectors and Aftermarket Cummins Oil Pan M11.

Maintaining your truck with the best parts is a way to prevent your heavy-duty truck from breaking down. Inform yourself and always do your research and notice any change when driving your truck.

Knowledge is power, and with the right information, you can keep your diesel engine truck running optimally, for less.

In recent reviews of diesel engine parts demand, it was surprising to learn from at least one company, AKMI Corporation, that there has been a high demand for oil pans on certain diesel models. What could cause such demand? Consider the possibility that the aftertreatment system is involved.

A check of recent technical service bulletins revealed that there is, indeed, a relationship among diesel aftertreatment malfunctions and engine oil condition. Not surprisingly, there is also a direct relationship between combustion malfunctions and engine oil quality. The following are some examples.

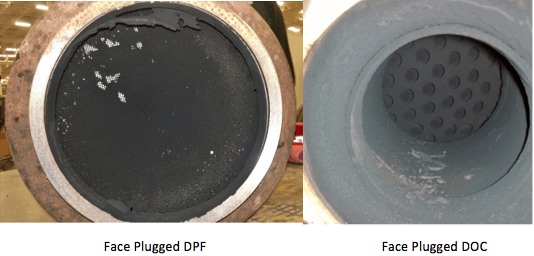

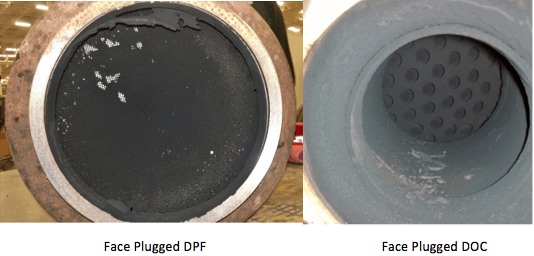

“If exhaust backpressure exceeds specifications, it is an indication that the DOC (Diesel Oxidation Catalyst) is face plugged. If a malfunction caused coolant to enter the exhaust system, it might become necessary to replace the DPF (Diesel Particulate Filter)”. In other words, the malfunctions in the aftertreatment system could cause exhaust backpressures to exceed the high limit. That, of course, leads to excessive combustion particulate matter (PM) to be forced past the piston rings and into the engine oil. Here are some photos that illustrate the aftertreatment component malfunctions.

Other bulletins refer to problems in the combustion chamber. One cites “carbon packing on the piston top land”. Another indicates a problem with “vertical liner lobing”. Both lead to excessive oil consumption. We can assume that they also lead to compromised combustion and higher soot levels, which would find their way into the oil pan.

So what do the above problems have to do with oil pan replacements. Simply put, the pan replacements could be due to alert service personnel going further than just changing contaminated oil. It is likely that they are pulling the oil pan as well and finding massive sludge deposits, such as shown in the upper photograph. That leads them to replace the pan and gaskets. It’s the sure way to deliver clean oil to the engine, without it being contaminated further from continuous suction of sludge by the oil pump and overloading of the oil filter.

The extended effects of the sludge contamination include turbocharger bearing failure and excessive cylinder wear. Where engine oil is compromised, many aspects of engine durability and performance will suffer.

What do you consider the most important engine part for your truck? Think of a part that your truck absolutely needs and can’t survive without. There are many different answers that can be given – cylinder block, crankshaft, camshafts, flywheel, exhaust manifold, EGR cooler, etc… (HINT…Oil Pan) I am sure that you can think of a few others that I haven’t listed. Pointing out one part exclusively is just too hard, so what would you list in your Top 5.

Now I ask, as you thought of your Top 5 engine parts, did the oil pan make your list?

No, why not? Is it too simple of a part for you to consider or is it because, unlike the crankshaft which has a vital role in engine movement, the oil pan just sits at the bottom of the engine block and has no “functional” use?

Myself, I would rank the oil pan in the Top 5 of the most important engine parts needed.

Even though it doesn’t connect with any moving parts, no gears to mesh with other gears, which in turn operate other parts, the purpose of the oil pan itself is vital. It stores one of the most important fluids your engine needs, which is OIL.

Without oil, all the other parts you can think of would not work to maximum efficiency and would eventually cause the engine to seize. Engine oil lubricates metal parts in the engines, so there is no metal grinding of parts. Without oil, these metal parts would grind against each other, causing small bits of metal to break off. Without proper lubrication, parts like the crankshaft, camshaft, and others would eventually seize up rendering the engine useless.

They store this crucial fluid, up to as much as 9 gallons of oil on Class 8 trucks. This much oil is needed as it does tend to breakdown and become thinner as the engine is used more. Oil pumps create a suction, pulling oil from the oil pan, running it through an oil filter, then through the engine before it ends up back in the oil pan.

If it is leaking, this could cause problems. Common leaks are gasket failure, drain plug or weld not secure causing a leak, or oil pan was hit and became cracked. Once an oil leak is discovered, then it’s very important to find the leak and fix it immediately. Sometimes this means having to replace your oil pan.

Overall, the oil pan is a very important and vital part of an engine, regardless of if it makes your Top 5 or not.

This isn’t because it’s a complex engine part with moving gears, but because the oil pan is responsible for storing one of the engines most vital fluids when it comes to function and performance.

Note: Below are links to Akmi oil pans by manufacturer:

1. Flywheels are typically found on vehicles equipped with manual transmissions, while flexplates are used in vehicles with automatic transmissions.

1. Flywheels are typically found on vehicles equipped with manual transmissions, while flexplates are used in vehicles with automatic transmissions.