When it comes to vehicle maintenance, many people may tend to overlook the cooling system.

After all, if the vehicle is not showing signs of overheating or you do not notice any leakage on the ground under the engine,

most would assume there is nothing to worry about.

Performing maintenance on the cooling system is more important than you think.

And is more than just adding new coolant and replacing a water pump when needed.

The maintenance process is relatively simple and consists of performing tasks that even people with no mechanical experience can do.

Here are steps for performing Cooling System Maintenance on your vehicle:

- Check coolant/antifreeze levels periodically and add coolant/antifreeze when needed.

- Look for any signs of leaking under the car, from the water pump, the hoses or the radiator.

- Check all the hoses connected to water pump and radiator.

- Pressure Test the radiator cap to ensure it is holding the proper pressure and not leaking.

- Check the thermostat – once the coolant reaches a certain temperature, the thermostat opens up allowing coolant to flow, regulating the coolant temperature. If the thermostat is stuck and will not open, it causes poor circulation and can lead to the engine overheating.

- Confirm the engine cooling fan is operating correctly.

- When replacing the water pump, flush the entire cooling system. Draining and replacing coolant is not enough. Flushing the cooling system removes any build-up of sediment or rust, which could prematurely damage the new water pump.

The most important thing is to remember to perform these tasks on a semi-regular basis,

which will help lead to longer engine life.

If you feel that you cannot do these tasks yourself or suspect that something may be wrong,

then take your vehicle to a trusted mechanic for further inspection.

Your vehicles cooling system is vital to engine performance and longevity.

If there is something wrong, the engine can overheat causing major damage like a cracked cylinder head or warped cylinders

– both of which are expensive repairs.

Make sure that you regularly check your cooling system to ensure long life for the engine in your vehicle.

The heavy duty aftermarket has seen many changes over the last 30 plus years. These changes have affected not only the sales of heavy duty truck parts, but the overall quality of the parts as well.

Commercial Trucks–1982:

- There were an estimated 3.6 million commercial trucks on the road.

- Two-Thirds of them were medium duty classification.

- Of the heavy duty trucks on the road, 50% of them were Class 6.

- Class 8 trucks only ran an average of 50,000 miles per year.

Commercial Trucks–2012:

- There is an estimated 4.4 million commercial trucks on the road.

- Class 8 trucks make up 65% of this number.

- Class 8 trucks run an average of 76,500 miles per year.

One would think, with significantly more heavy duty trucks on the road, replacement parts would be in high demand. As technology has improved, the quality of parts has improved.

Expected Parts Mileage:

- In 1982 an alternator would last an average of 132,000 miles, clutches an average of 171,000 miles and a Class 8 engine would be overhauled at around 276,000 miles.

- Today, an alternator would last an average of 278,000 miles, clutches an average of 369,000 miles and a Class 8 engines would be overhauled at 680,000 miles.

- Technology has increased the life of heavy duty truck parts, so they do not need to be replaced as often. Most truck owners today may never replace a clutch or overhaul an engine.

Federal emissions regulations have also impacted the Aftermarket industry. Over the last 5 years, new regulations are being enforced on trucks to have cleaner emissions. More often than not, it’s more prudent to buy a new truck that already meets these standards, then try to convert the older truck.

It has been noted that there is a “sweet spot” for the aftermarket when a Class 8 truck is 7-8 years old. This is when major components of the truck may need to be replaced, or an overhaul of the engine may need to be done. Any extended warranties would be ended by this time, and truckers/fleets would be looking at aftermarket sources to fill their heavy duty truck parts needs. Besides overhauling the engine and replacing parts, the only other options would be to purchase a new truck or glider kit-built truck.

Heavy Duty Aftermarket (Class 6-8)-1982:

- $9.3 billion dollar business

- The percentage of heavy duty truck parts being sold in the aftermarket – power generation-40%, power transmissions-23%, undercarriage business-18%, electrical-11% and other parts-8%

Heavy Duty Aftermarket (Class 6-8)-2013:

- $22 billion dollar business

- The percentages of heavy duty truck parts being sold in the aftermarket – power generation-34%, undercarriage-21%, power transmissions-14%, cab/chassis-13%, electrical-8% and other parts-10%.

The aftermarket industry is crucial to keeping transportation & shipping industries on the road today and for many years to come.

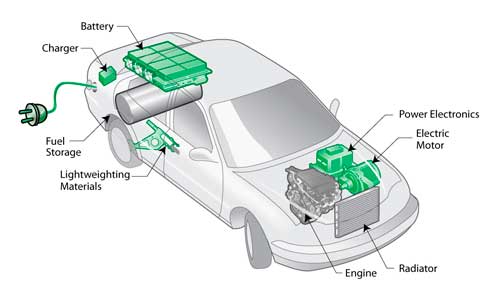

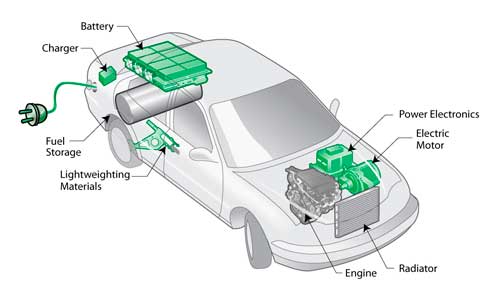

Recently I had been researching hybrid vehicles and technology to learn about them and maybe in future purchase a hybrid vehicle. While web surfing hybrids, I came across an article on the www.theguardian.com website that caught my attention. The title was “Can flywheel technology drive out the battery from car hybrids?” The article discusses the potential of a flywheel-based Kinetic Energy Recovery System (Kers) that could potentially replace the battery in hybrids. These vehicles are known as “Flybrids”

Before discussing these ‘flybrids’, here is some information on hybrids that I found to be interesting:

- Hybrid technology was first used in 1900 and in 1901, Ferdinand Porsche developed the Lohner-Porsche Mixte Hybrid, the first gasoline-electric hybrid automobile in the world. An interesting notation that I had found on Wikipedia.

- The Toyota Prius was the first mass produced hybrid vehicle and helped create the current hybrid craze that is going on today.

- 7.5 million hybrid vehicles have been sold through December of 2013 since they became massed produced in 1997, 6 million of these are Toyota Motor Company owned between Toyota & Lexus brand names.

- In 2009, the U.S. House of Representatives approved the ‘Heavy Duty Hybrid Vehicle Research, Development & Demonstration Act of 2009’ for heavy duty plug-in hybrid vehicles.

- According to Pike Research, the estimated global market of hybrid medium/heavy duty trucks & buses on the road was 9,000 vehicles in 2010 and expected 100,000 vehicles in 2015. Coca-Cola Enterprises has the largest fleet of hybrid trucks in North America.

Hybrid heavy duty trucks can haul some weight as well. Freightliner Hybrid technology was boasting their new line of trucks having a Gross Vehicle Weight Rating up to 55,000 lbs, a range of 200-320 hp, with torque output ranging from 520-750 lb/ft. These trucks can move/haul just about anything standard diesel engine trucks can as well. If you are in market for a new truck, you should give a hybrid truck a second look.

Now I want to reflect on the ‘flybrid’ article a little bit more. Flybrids are not only for automotive vehicles. There are buses in London currently operating with flybrid engines as a test run, with some also expected in Northern Ireland also.

The concept of the flybrid is, the kinetic energy recovered during braking would spin a flywheel. The recovered energy is stored in the spinning flywheel, to be released upon acceleration. The amount of energy a flywheel can store depends on its mass and the speed at which it is rotating. Certain prototypes have provided up to 80 bhp boost.

Flywheels are lighter than batteries and are easier to dispose of when they go bad. A flybrid engine offers a prospect of improved fuel efficiency as well. Unlike batteries, you can charge a flywheel up & slow it down multiple times without the degradation of performance.

Car manufacturers such as Porsche, Jaguar, Audi & Volvo have begun to experiment with flybrid technology in recent years. Audi Sport’s flywheel hybrid, the R18 E-Tron Quattro, became the first hybrid vehicle to win the legendary “Le Mans 24 hour endurance race.”

As intriguing as this flybrid and Kers technology is, I would not expect a big exploding trend just yet for flybrids on the market just yet. Toyota themselves haven’t shown interest in flybrids, and the major companies who have do not feel the technology is ready for mass production at this time.

In another 5 years or so, you could be debating, Hybrid or Flybrid, when it comes to your next vehicle purchase.

Marine exhaust systems are an important part of marine engines, but are often overlooked. When it comes to the exhaust systems, there are two main options for recreational boats: Wet or Dry.

Ever wonder why a marine exhaust manifold looks like a big square piece of metal versus an automotive exhaust manifold with its tubes more prominent. The main reason is to accommodate the flow of water mixing in with the exhaust fumes, this type of manifold would apply to a “Wet” exhaust system.

All Wet

A wet exhaust mixes seawater with the exhaust before it can be routed out of the boat. Injecting seawater into the exhaust can dramatically lower the temperature of exhaust run, which reduces risks of fire or being burned by an exhaust pipe.

The water is provided by a dedicated seawater pump which in turn routes water through the engine lube oil cooler, gearbox cooler and main heat exchanger prior to being injected into the exhaust downstream of the exhaust manifold itself.

Bone Dry

This is a dry exhaust system (no seawater is present) and produces high temperatures. Diesel exhaust gases can reach as high as 1200 degrees F. This means that special “lagging” or insulation needs to be added to surrounding areas or parts, to protect surrounding equipment, boat structure and people.

Since no water is used in the exhaust, there are different options in regards to engine cooling. A heat exchanger can be used and seawater would simply be discharged overboard. Another common alternative would be moving the entire heat exchanger outside of the boat. The passing water would carry away the heat, much like a radiator does for a car.

While wet exhaust systems are much more common for recreational boats in general, many builders of deep-sea passage makers prefer to use dry exhaust systems on a number of their models.

Wet Exhaust – Pros & Cons:

- PRO – Far fewer heat issues with exhaust runs.

- CON – Seawater pump failure could destroy the engine.

- PRO – More Interior Space

- CON – Extra maintenance for the sea strainer, pump and injector elbow

- PRO – Easier to design and install

- CON – Exhaust can blow into boat in following wind.

Wet exhaust systems also require a hole in the boat for the intake which requires extra sealing. If the pump fails or strainer is clogged, engine temperature would begin to rise and set off alarms. You may only have a few seconds to shut down your engine before major damage is done.

There is also the potential of flooding the engine when over cranking at engine start-up. Too many unsuccessful starting attempts could dump enough water into the exhaust flooding the turbocharger, exhaust manifold, cylinders and cause catastrophic damage to an engine.

Dry Exhaust – Pros & Cons:

- PRO – No seawater pump to maintain, or have fail

- CON – Dangerous heat levels

- PRO – No seawater strainer to maintain, or have clog

- CON – Space accommodations for stack (less interior space)

- PRO – Exhaust released well above deck

- CON – Complex Design and construction

With dry exhaust systems, most frustrations come from the design of the exhaust rather than the performance or maintenance. There are less parts to worry about, which means not as much maintenance needed. The biggest challenge is insulating/shielding parts so the heat is not damaging other parts, boat structure, or burning the people who have to service the engine.

While wet exhaust systems appear to be more common, especially with recreational boats, they also require more maintenance and replacement parts.

If you can take the heat and like better reliability, then a dry exhaust system may be the best option.

Have you ever heard the phrase ‘Built like a Mack Truck’ and ever wondered where it came from. Maybe you are a truck mechanic who is replacing heavy-duty truck parts on a Mack truck and you thought about where the saying came from. Or you could be a commuter who noticed a Mack truck on the road and was curious about its history. At some point in time, I think everyone has heard the saying and probably was curious where it came from.

Mack Trucks have been an American staple since the 1900s and is one of the first big-name truck manufacturers to have sustained success for more than a century. Kenworth began a business in 1912, Freightliner was developed in t

he 1930’s and Peterbilt was established in 1939.

Who made mack trucks?

If you want to know the history of mack trucks, you have to start with the creator.

John M. Mack, known as “Jack” and his brother Augustus purchased the wagon company that John worked for in 1893.

The following year, their brother William joined operations. The brothers began experimenting with steam-powered and electric motors.

Inspired by the Wright Brothers-Orville & Wilbur, Willis Carrier, and Henry Ford’s inventions, John Mack had a vision about producing heavy-duty trucks, engines, and replacement parts.

Company

The “Mack Brothers Company” was founded in 1900 and the company opened its first bus manufacturing plant the same year. A sightseeing company had placed the first order.

Mack’s first truck was manufactured in 1907.

During World War I, Mack delivered over 6,000 trucks to the American and British military for use during the war. Rumor has it that the British soldiers were so impressed with the Mack Trucks durability, toughness and reliability they gave them the nickname of “Mack Bulldogs” after their own British Bulldogs.

Mack truck logo history

The history of mack trucks logo?.

The history of mack trucks logo?.

In 1922, “Mack Brothers Company” changed its name to Mack Trucks and the bulldog was accepted as the company’s corporate Logo.

The bulldog was first portrayed on a steel plate mounted to the side of the truck, the hood ornament appeared approximately 10 years later. These trucks with a gold plated bulldog indicate that the truck is made entirely of Mack parts, while built with another manufacturers’ transmission, engine, rear axles or suspension are given the chrome-plated logo.

Manufacturing

Mack Trucks made a name for themselves by being tough and reliable trucks.

But they offered many advancements to heavy-duty truck engines and their parts as well.

In 1918 they became the first manufacturer to apply air cleaners and oil filters to their trucks.

In 1920 became the first truck with power brakes.

Also became the first manufacturer to produce their own diesel engines in 1938.

Engines history

Jumping ahead to the 1960s, vice president of product and engineering, Walter May, had developed the Maxidyne high torque rise engine, first as an inline V6 and later a V8. The development was an industry-changing event, as it allowed a Class 8 heavy-duty engine to operate with a 5-speed transmission. Previously trucks would have 10 gears’ or more.

Mack Trucks is a top producer in the vocational “on-road-vehicle” Class 8 through Class 13.

They are also among the most popular manufacturer of heavy-duty “off-road” trucks in America. Are also sold worldwide in 45 different countries.

Their main assembly plant is located in the state of Pennsylvania and has the capability of manufacturing all known heavy-duty Mack Truck Parts.

For more than a century, Have been prominent on American roads.

Their durability to withstand world wars, rising competition, and the test of time is a testament to the brothers that first had a dream and made it come true.

Do you know of anything that is ‘Built like a Mack Truck?’

This car is a legend. That’s all we have to know. We don’t need numbers and figures to prove the charisma of an icon, we just know. However, the Volkswagen Beetle has so much to say, and they’re not just boring facts, but a cool story to how it became our favorite bug. Maybe that’s why we came to love bug beetle in the first place. So why don’t we refresh our memories and take a road trip back to where it all happened, then arrive at why we think it is legendary. Seatbelts?

I told you this would be interesting. Even Hitler was a fan! This was in 1938, three years after Dr. Ferdinand Porsche, the man beside Hitler and the mastermind of Beetle’s unique design, created the Volkswagen which means “people’s car” in German. He later created his line of cars and named it after him. Ring a bell?

How born the VW beetle idea and the love of bug beetle

If you are curious and you love the beetle you have to know a little bit of its story first.

In 1931, Ferdinand Porsche and Zündapp developed the Porsche Type 12 the first Volkswagen, the “Auto fur Jedermann” which means “the car for everyone“. Porsche had already developed a four-cylinder boxer air-cooled engine and Zündapp was developing a water-cooled 5-cylinder radial engine. Porsche had chosen a torsion bar rear suspension by Edward Rumpler.

In 1932, there were already three prototypes, and later a fourth in 1933, the Porsche Type 32, built by the NSU motorcycle factory.

Adolf Hitler loved bug beetle since its born.

In 1933, Adolf Hitler commissioned Porsche to design a car for the people (literally in German, Volks Wagen). The car should have a capacity for two adults and two children, with room for suitcases and be able to reach 100km/h. The German National Socialist Party had already used the term “Volks” for other party-sponsored products, such as the Volksradio.

However, the name Volkswagen would not be the official one until a few years later. This new vehicle was initially named Porsche Type 60 and then baptized as KdF-Wagen. KdF was the initials of Kraft Durch Freude (Strength through Joy), the leisure section of the Third Reich.

The first prototype released was in October 1935, the Type 60, known as the V1. In 1936 tests began with the three V3 prototypes manufactured at Porsche’s Stuttgart facility. In 1937, the 30 W30 models, manufactured by Daimler-Benz, already accumulated 2,900,000 km of tests. All vehicles already had the distinctive rounded shape and air-cooled engine at the rear.

Hitler’s plans and his love for the bug beetle were to make this new vehicle available to everyone and for that, he introduced a form of fractional payment. Consumers would buy a “Sparkarte” (a coupon booklet) for 1 Reichsmark, equivalent to about 25 euro cents. After buying the coupon book, you had to buy at least 5 Reichsmarks in coupons a week. The total price that for the basic vehicle was 990 Reichsmark.

In 1938, the Stadt des KdF-Wagens was built around the village of Hesslingen which was where the workers of the KdF-Wagen factory lived.

When World War II broke out in 1939, only a few units had been for consumers.

The war and the beetles

The two main vehicles produced during the war were variants of the Beetle, as the four-cylinder boxer air-cooled engine and rear torsion bar suspension was ideal for the harsh desert conditions in Africa.

Firstly was the Type 82 Kubelwagen, a very basic all-terrain utility vehicle. German military officers had stipulated that the total weight of the fully-loaded Kubelwagen (including 4 soldiers armed for battle) should not exceed 950 kg, leaving the maximum weight of the unladen vehicle at 550 kg. Porsche subcontracted Trutz, an experienced manufacturer of military vehicles, to collaborate on the body design.

The first successful tests were out in 1938 and continued in Poland in 1939. The result of these tests prompted the German military to ask for some important changes. Although the vehicle had shown impressive results on all terrains, even compared to some 4x4s that already existed at the time, the military thought it could be improved, and that the minimum speed of the vehicle had to be reduced from 8km/h to 4km/h in order to match the troops’ walking speed.

Porsche gearboxes

Porsche responded to these requests by installing “gearboxes” (what in practice was a second gearbox with a higher torque), larger wheels and a revised suspension. The gearboxes together with ZF’s self-locking differentials increased the vehicle’s all-terrain capability and made it possible to reduce the minimum speed to match the pace of the troops. Kubelwagens began mass production as soon as the factories at Stadt des KdF-Wagens were finishing.

The second vehicle produced during this period was the Type 166 Schwimmwagen, based on the Kubelwagen 4×4 prototype. The Schwimmwagen was an amphibious all-terrain vehicle using an extended crankshaft that operated a folding propeller at the rear of the vehicle.

This propeller coupling was so simple that the Schwimmwagen could only use the propeller to move forward. To reverse it was necessary to paddle or use the ground wheels to reverse slowly.

The Beetle Turbo

Volkswagen Beetle Turbo

Presenting the Beetle Turbo another reason for our love for bug cars. Convertible sculpted from powerful cosmetic enhancements. It’s an extensive package composed of performance-inspired perks and detailed sleek. You can still sniff the original one’s charm, but this one’s created to suit our contemporary needs. What a beauty!

Re-designing the Beetle is like a noob going head to head with the Godfather. The chances are slim. But why do people still applaud the Beetle despite its evolution throughout the century? May it be the name, the design, the movie, or its story, the Love Bug lives on! It’s legendary, and that’s all we need to know.

The history of mack trucks logo?.

The history of mack trucks logo?.