Let’s say you are a new start-up company and you have a fleet of heavy duty trucks. You have some experience in the trucking industry, but feel it would be too costly to keep in-house mechanics and maintain your fleet.

Finding trained & skilled mechanics is not cheap, but the risk of hiring one trained person and hoping he can train unskilled labor is one you don’t want to take.

Then maintaining your inventory of commercial truck parts for your fleet can be challenging and ending up with too much of one item and not enough of another can lead to longer downtimes for your vehicles.

So after looking at the cost and risks of an “in-house” maintenance program, you decide that you would rather outsource the repair work. How do you know which shop will be the best for your fleet needs?

Working for a company that sells commercial truck replacement parts on a wholesale level, I had never thought about it before.

Being a wholesaler, our company doesn’t deal with the general public. We have referred callers to our closest customer in their area before, but had never given a thought about repair shops in general.

Not until a caller asked me if any of his choices were a repair shop as well, so I decided to do some research.

Now since I still do not have a need for a repair shop, I researched on how to go about finding the right repair shop for your needs.

Here is a list of some ideas to consider when looking for a repair shop:

- Make an initial list of the repair shops in your area and begin by looking at the website, if offered.

- A professional or user friendly website can be a sign the company conducts itself professionally.

- Call up the companies on your list and evaluate their customer service. Are they willing to take the time to speak with you on the phone or are they rushed and trying to end the call quickly? Depending on how these calls go, you could eliminate some companies from your list.

- Review the list of services provided. Some repair shops may only specialize in one area of repair work, meaning you would have to find another shop for other repairs.

- Make sure the repair shop does work on your vehicle brand/application. If you have a truck with a Aftermarket Detroit S60 engine and take it to a shop who specialize in Caterpillar, you may not get the best repair work done.

- What is the labor rate of the shop and hours of operation?

- Ask about their technician certifications and experience.

- What is the vehicle turnaround time for repairs and their service backlog look like? A shop could do quality repair work, but if understaffed, they could take longer to get your truck up & running.

- Does the repair shop maintain an internal inventory of commercial truck parts, or would parts have to be ordered and shipped to them? You may have to wait a day or longer to get your truck back on the road.

- Make sure the repair shop has good insurance coverage. Last thing you would need is for some sort of accident to happen, or the building burns down, and the repair shop insurance won’t cover your truck.

- Will the shop offer a warranty on their labor?

All of the things listed above are great, but feeling comfortable with the company is just as important. Another thing to consider, just because a company is the cheapest option, doesn’t necessarily mean they are the worst option. The same thing can be said about speed as well.

Granted, you want your truck on the road as soon as you can get it there, but you want it to last for a long time as well. Quality repair work can help make that happen.

If you are running vehicles multiple hours a day or in some form of a professional racing league, having your parts professionally coated is probably your best option. But what about the average guy who is looking to restore their dream car, but is on a budget. Do-it-Yourself options can help save some money.

Deciding what brand name or type of coating would be the most difficult choice.

They have cans that look like traditional paint and used in paint sprayers, or Aerosol can options. The Aerosol can option may not always be ceramic coatings, they may just be high-temp resistant paint. If you have an air compressor and access to a paint spray gun that would be best. Even a cheap spray gun from a local supply store would work.

Steps to ceramic coating of your engine parts

Let’s say you want to put a ceramic coating on your exhaust manifold, here is what I have found to be the basic steps:

- Make sure you clean the entire exhaust manifold inside as well as the outside. Professionals will have fancy chemicals to help assist them, but a strong household degreaser can work just as well.

- Then you would want to sandblast the manifold to remove any loose pieces or dirt the degreaser couldn’t remove. If you do not have a sandblasting tool or access to one, then you can use steel wool or sandpaper. It may take longer to do, but prepping the surface is a must.

- Prepare your work area. Lay down tarps and cover anything (in immediate area) that you do not want to be painted. If possible, hang the part(s) by a wire, so the manifold or its pieces are suspended in the air. This would be an ideal position for painting, but not necessary.

- Put on a safety mask or respirator, gloves, safety glasses and make sure you have plenty of ventilation if working in a garage or home workshop area.

- Before you begin to spray, make sure you read the instructions on the label of the product you purchased.

- Spray an even coating over the entire piece(s). Allow a few minutes to dry before applying multiple coats.

Curing process

After applying the final layer to your exhaust manifold, the curing process is next. Professionals have industrial ovens and other heating equipment that can begin the curing process no problem. Using a conventional oven that can reach a temperature of 500 degrees can work, but you wouldn’t want to use the oven from your kitchen. Without access to an oven or a heat gun, you would need to let the manifold dry for at least eight hours.

The final stages of the curing process occur while the parts are installed on the engine. You want to start the vehicle and let the engine run on idle for at least an hour, or drive the vehicle around. Then let your engine cool down completely and repeat the cycle. This may need to be done a few times, refer to the product instructions.

High temperatures

One important thing to note is that excessive heat from a poorly tuned engine can actually damage the ceramic coating of your exhaust manifold or other coated parts. Make sure all adjustments to camshafts, springs, valves, timing, and fuel injection system are done, otherwise all the time spent coating your manifold and other parts could be time wasted.

Whether you are looking to restore your dream car, or you would like better performance and protection for your everyday car, the do-it-yourself option for ceramic coating can save you some money that can be used for different areas of your vehicle.

Benefits of ceramic coating your exhaust manifold

- Increase performance reducing the backpressure.

- Surface temperature reduction: Heat at those levels is enough to do serious damage to internal parts of the vehicle.

- Prevent corrosion: Ceramic has high resistance and is very durable.

Exhaust manifold ceramic coating cost

The price really depends on the version of your exhaust manifold, each part needs a process before applying the ceramic coating. So the prices can be around 40$ to 250$ or more. (Remember that there are estimates)

The heavy-duty trucking industry has a big demand for qualified truck drivers. There is also a need for qualified mechanics/technicians that are knowledgeable in repair work and know to use quality replacement diesel engine spare parts. If you like this world and the truck maybe you have to study a truck driver career

The freedom of the open road and driving cross country hauling freight doesn’t appeal to the younger generation. Most people, myself included, look to pass trucks while on the freeway and hate getting stuck behind them.

Short-haul driving (within city limits) doesn’t appear to be that appealing either. No one likes traffic, to begin with, and being stuck in the city with a truck & trailer three times the size of the average car daily doesn’t sound fun.

Truckinginfo.com posted an article in December of 2013 titled “Commentary:

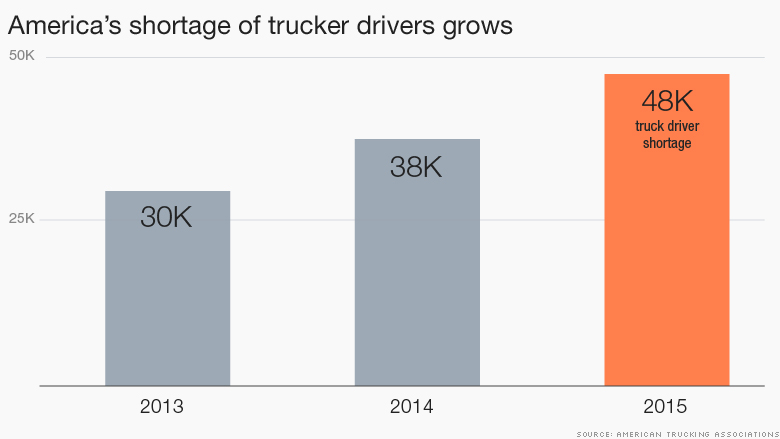

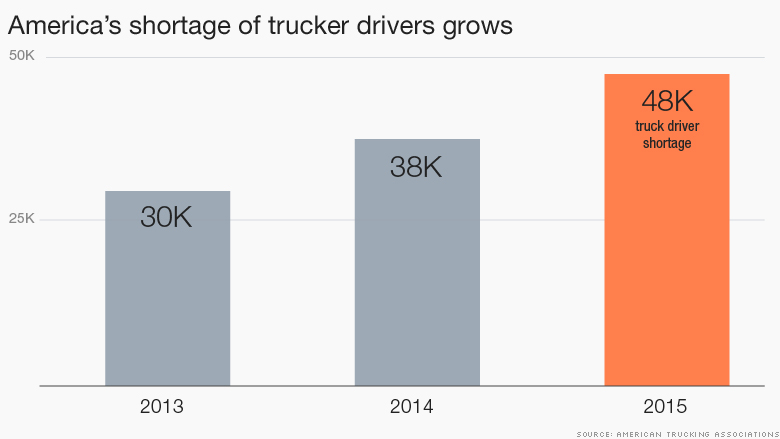

The Ever-Pressing Need for Young Drivers and Technicians”. This article mentions that the average age of current drivers is 55+, as provided by the Bureau of Labor Statistics. It’s also mentioned that by 2020, there can be a need for 330,000 new drivers.

How to become in a heavy-duty truck driver

1. Requirements

If you want to become a truck driver you have to accomplish these requirements for the school you are gonna apply.

Obtain a CDL

The first step is to obtain a Commercial Driver’s License (CDL) from your state of residence, which comes with its own set of requirements.

Attend a Truck Driving School

To earn a CDL, you’ll have to attend a truck driving school. Each school may have slight variations in its truck driver requirements, but there are a few qualifications that are consistent across the board. If you’re wondering where the nearest school is or how you’ll pay for school.

Clean Driving Record & Solid Work History

Most truck driving schools require a clean driving record and a solid work history to enter their programs. Want more information on truck driver qualifications in your state? Pick up a copy of your state’s commercial driver’s manual at your local Department of Motor Vehicles (DMV) to become familiar with commercial driving rules and regulations.

Be at least 21 Years Old

The Department of Transportation (DOT) requires all professional truck drivers to be at least 21 years old.

Pass a Drug & Alcohol Test & Undergo a Physical

Prospective drivers also have to pass a drug and alcohol test and undergo a physical by an approved doctor before receiving their CDL.

2. Find a truck driver school

You have to find a good school that teaches you the necessary skills to be an excellent and prepared truck driver.

3. After you complete your preparation you have to find a job as a truck driver.

You can apply for this job on the Internet or in Institutions of truck drivers in your country.

We provide you some free job boards for this career on this web page.

3 benefits of the truck driver career

1. Stability and good pay

With a truck driver career, you have a lot of work opportunities in different companies and the job is well paid.

The median annual wage for a trucker that works for a private fleet,

such as a truck driver employed by Walmart, is $73,000, according to ATA.

The Labor Department pegs the median annual salary for all truck drivers at around $40,000.

2. Traveling.

As a truck driver you are gonna have a lot of travels and adventures around your country, that´s the reason why a lot of truck drivers love their jobs.

3.Freedom

you are not going to have a boss or other people disturbing you, you don´t have to deal with other employees or other things like that. You can take different ways to do your job, for example, you can be a local driver, a road driver, tanker driver and other different opportunities that you have as a truck driver.

Here are some misconceptions of being a truck driver:

- The stigma of super long days or terrible hours.

Most truckers will work longer days on average than most, but with new safety regulations and limits on how many hours a trucker can drive, it’s not as bad as it used to be. Trucking companies will need drivers at all times of the day, so different shifts are available.

- Older trucks are not the easiest to drive.

While driving a manual transmission truck does take more focus and concentration, many newer trucks have automatic transmissions, so they will be easier to drive.

- Short Haul drivers complain the company does not have enough drivers, hours are too long and not being appreciated.

Estimated shortage

Wikipedia noted that in 2005 there was an estimated shortage of 20,000 drivers and expected this number to increase to 111,000 by 2014. At one point, driver turnover for trucking companies was 136%. More drivers were either retiring, quitting, or being let go, they’re being hired as replacements or new drivers. It’s no  surprise that the short-haul drivers complain as they do.

surprise that the short-haul drivers complain as they do.

The article from Truckinginfo.com goes on to mention that the need for technicians/mechanics is worse than the need for drivers. The Department of Labor estimated 10 years ago there were 606,000 diesel technicians and the industry would need 205,000 more by 2014 to fill new positions and replace retirees.

Repair work

While the weight of diesel engine spare parts may not be a good reason, the complexity of the parts can be one. Also, the repair work may be harder compared to the automotive. Diesel engines and their spare parts are bigger/heavier than automotive engines and parts, but the repair processes are very similar.

When people think of a diesel mechanic, their first thought is probably of an overweight older gentleman, covered with grease spots and an outdated workshop. There are probably places like this, but most certified repair shops are very clean and professional.

Importantly the pay scale for drivers and technicians is comparable to other careers and geographical areas.

Years of experience and quality of work can be factors as well.

So, how can the shortage be overcome?

Creating more public awareness about the positives involved with being a truck driver or technician is one way. Having programs that can reach out and educate high school kids about careers in these fields can go a long way. Not all high school kids go on to college. Some kids may look at going to vocational schools for specialized training or they learn on the job.

Big time truck builders such as “Navistar, Peterbilt and Volvo” have established alliances or vocational training programs with schools like Universal Technical Institute (UTI) or Wyotech to help improve and educate recruits for a career as a diesel technician.

If you are at a crossroads in life or just looking for a career change, there is plenty of room in the trucking industry as a driver or technician.

As a purchasing manager for an aftermarket heavy duty replacement truck parts supplier, it is my responsibility to research parts and determine the best parts to add to the inventory.

There are many factors to consider when it comes to adding parts to existing inventory. Age of the part, demand for the part, and quality sourcing are all important. Knowing what parts to start with and the basic information of the part are crucial.

Listening to customers is one of the best ways to figure out what new parts are on the rise. Customers at some point in time will ask the salesforce about a part number that is not in stock or currently available by the company. When this happens, is your salesforce prepared to get the information you will need to make it easier to research the part in question?

Here is a list of questions the salesforce team can ask the customer:

How often do you sell this particular part?

Product demand will help in determining a part. You wouldn’t want to add something that a customer only replaces once a year.

What year is the truck?

Newer trucks will have manufacturer warranties up to 5 years or more. During this time, parts are covered by the warranty, so aftermarket heavy duty replacement truck parts are not needed until the warranty is expired. There is not many older trucks, 35 years or older, that are still roadworthy. Adding new inventory parts for trucks this old would not make sense.

Do you see a wide variety of this type of truck or engine types?

Different geographical areas tend to see more of one type of truck/engine than another. One customer could see more Aftermarket Detroit Diesel engines versus Mack engines.

What is the OEM cost to replace the part?

Aftermarket options need to be of good quality, but also need to be priced as such that it is worth going with the aftermarket part instead of OEM.

Besides polling the salesmen for information, reviewing customer purchase history can be useful. If a customer is purchasing many types of Aftermarket Cummins heavy duty truck replacement parts, you can conclude that they would be open to more Aftermarket Cummins part options.

Let’s say you have a list of some part numbers to research. This list was finalized after speaking with your salesforce and reviewing customer histories, but you are still unsure if you should add this part. Another way to get some information on a part is by doing a ‘Google’ or other web browser search.

Type the part number and part type in the search bar and see what comes up. If the first few pages show multiple listings of this part for retail sale, whether it’s used, remanufactured or new, you more than likely are looking at a part number that is in demand now.

If all you come across in your search are overseas companies looking to sell this part number and no retail listings, you may have an oddball part that isn’t in demand. Either this, or the part is still being covered by manufacturer warranty and will not be in demand for a while. It could be possible that you are using an older part number and should check for alternates to confirm.

Before you add any heavy duty replacement truck parts, be sure you research the parts very carefully, then look for your sourcing options.

What Does It Mean to You?

In January of this year, a new Memo of Understanding (MOU) was reached between a number of medium and heavy duty commercial vehicle manufacturers and the Aftermarket providers of vehicle service. This historic agreement applies to the OEM release of all technical information and programming protocols necessary to maintain the emission controls on the vehicles to which it applies.

What this means is that the maintenance of the complex integrated emission controls, such as on-board computers, EGR valves and EGR coolers, exhaust manifolds and piping, diesel particulate filters and selective catalytic reduction systems, are now to be maintained by ANY facility that purchases licenses from the vehicle and engine manufacturers who provide the original components. The agreement applies to medium and heavy duty vehicles over 14,000 GVW and manufactured after 2009. It excludes motor homes and vehicles with off road engines.

The first laws concerning RTR were enacted by the State of Massachusetts. The new MOU is not legally binding, but is an indication of the recognition of the need for freedom of maintenance choices by owners of commercial trucks. It also provides the means by which every heavy duty vehicle will remain emissions compliant throughout its years of service. Below are some examples of the need for constant vigilance for the causes of emission control failure:

In the first photo, the EGR cooler jacket has become clogged with diesel particulate matter (PM or Soot).

In the second photo the EGR cooler has cracked internally and allowed coolant to leak into the entire exhaust system and into the engine oil.

The provisions of the MOU are extensive and very important for the repair facility to understand and apply. They include:

1. The OEs will supply the same information and same limitations that they give to their dealers.

These include:

- Location of critical sensors.

- Wiring diagrams.

- Ability to reflash on-board computers.

- As-built VIN to OE part number information, often called line settings.

- Any specialized tools.

- The OEs WILL NOT SUPPLY TRAINING.

2. Licensing at fair and reasonable prices.

3. Light/HD OEs may adopt the existing automotive MOU.

Implementing the RTR requires attention to the makes and models for which licensing should be sought. The licenses are not inexpensive. Secondly, extensive training of expert technicians is required if reprogramming of vehicles is contemplated. Every OE has its own protocol which can be run off of the same PC with common interface cabling as long as the licensed software has been downloaded.

With this momentous agreement, the entire vehicle service industry should now be able to agree on common practices that insure the quality of maintenance required in today’s commercial vehicles.

What do you consider the most important engine part for your truck? Think of a part that your truck absolutely needs and can’t survive without. There are many different answers that can be given – cylinder block, crankshaft, camshafts, flywheel, exhaust manifold, EGR cooler, etc… (HINT…Oil Pan) I am sure that you can think of a few others that I haven’t listed. Pointing out one part exclusively is just too hard, so what would you list in your Top 5.

Now I ask, as you thought of your Top 5 engine parts, did the oil pan make your list?

No, why not? Is it too simple of a part for you to consider or is it because, unlike the crankshaft which has a vital role in engine movement, the oil pan just sits at the bottom of the engine block and has no “functional” use?

Myself, I would rank the oil pan in the Top 5 of the most important engine parts needed.

Even though it doesn’t connect with any moving parts, no gears to mesh with other gears, which in turn operate other parts, the purpose of the oil pan itself is vital. It stores one of the most important fluids your engine needs, which is OIL.

Without oil, all the other parts you can think of would not work to maximum efficiency and would eventually cause the engine to seize. Engine oil lubricates metal parts in the engines, so there is no metal grinding of parts. Without oil, these metal parts would grind against each other, causing small bits of metal to break off. Without proper lubrication, parts like the crankshaft, camshaft, and others would eventually seize up rendering the engine useless.

They store this crucial fluid, up to as much as 9 gallons of oil on Class 8 trucks. This much oil is needed as it does tend to breakdown and become thinner as the engine is used more. Oil pumps create a suction, pulling oil from the oil pan, running it through an oil filter, then through the engine before it ends up back in the oil pan.

If it is leaking, this could cause problems. Common leaks are gasket failure, drain plug or weld not secure causing a leak, or oil pan was hit and became cracked. Once an oil leak is discovered, then it’s very important to find the leak and fix it immediately. Sometimes this means having to replace your oil pan.

Overall, the oil pan is a very important and vital part of an engine, regardless of if it makes your Top 5 or not.

This isn’t because it’s a complex engine part with moving gears, but because the oil pan is responsible for storing one of the engines most vital fluids when it comes to function and performance.

Note: Below are links to Akmi oil pans by manufacturer:

surprise that the short-haul drivers complain as they do.

surprise that the short-haul drivers complain as they do.