All mechanics understand the importance of flywheels when it comes to engines. They have to be strong, sturdy, handle the rigors of everyday hauling, yet remain perfectly balanced to provide their most efficient form of energy.

When it comes to replacing your flywheel, how involved do you get?

Do you stick to only OEM replacement or do you look for value with an aftermarket replacement?

OEM replacements are the safest way to go, as they are being supplied by the engine manufacturer directly, but they are also the most expensive way to go. If your truck is less than 5 years old, more than likely any replacements would be covered by warranty.

But what if your truck is 10 years old, or the OEM replacement isn’t available for a couple of months and you need to get your truck back on the road. These are scenarios where an aftermarket replacement option would be needed.

When the situation calls for an aftermarket replacement flywheel, letting your trusted mechanic pick the option can be the easiest way to go, but do you know what you are actually getting?

There are so many different aftermarket flywheels and suppliers, one needs to be careful when choosing a type or brand. Remember, your local mechanic is running a business and while a good mechanic looks into longevity/quality of a part, there are a lot of them that are just interested in the “best price available” and hope that nothing goes wrong during the warranty period.

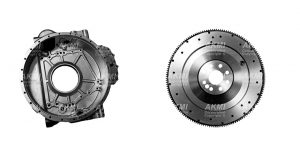

When comparing one aftermarket replacement to the next, you need to go deeper than just looks and if it mounts correctly. If you were to place multiple aftermarket flywheels next to each other, it would be impossible to know if one is better than the other just by looking at them. They would all have the same mounting pattern, the same specifications, and be within the same approximate weight. Visually, these flywheels appear to all be the same, now what?

This is when you’d want to do some research on the companies that are providing the aftermarket replacement part you are looking for. Here are a few things to consider when researching companies:

How long have they provided the specific part you are looking for?

If one company has been providing flywheels for 20 years, while another company just 2 years, this speaks towards the experience of the company. You may feel safer going with the company who has been doing this for 20 years, but the experience isn’t the only thing to consider.

What is the reputation of the supplier, their warranty terms on parts and how do they handle their warranty claims?

Some companies may only be willing to offer a 6-month warranty, while others are willing to offer 12 months or longer. Longer warranty normally speaks to better quality as the company is willing to state their product lasts longer.

How a company handles or processes warranty claims is important as well. Do they follow and uphold the terms of their warranty in a professional and ethical manner? Do they try to delay the claim process by asking questions or requesting information that may not seem related to the matter at hand? All suppliers, even top-notch companies, have to occasionally deal with a faulty product. How these companies handle the situation can tell you a lot.

What country is the part manufactured in?

The quality of material from some countries have bad reputations for being so poor in quality that the U.S. has added extra fees they call “Anti-Dumping Duties”. These duties are applied to certain products that are manufactured using these poor quality materials.

Not all factories in these countries use “poor quality material”, but when you start putting all the information together – Country of Origin, Company Experience, Company Reputation & Warranty and Cost of Product, you’ll be more prepared to make the best decision.

When it comes time to replace your flywheel or any engine part and you are looking at aftermarket replacements, make sure you get involved and ask questions about the source.

Flywheels: The Basics

Heavy rotating disks that build up very high mass & are connected to a rotating shaft. They are often used to provide continuous energy in systems where the energy source is not continuous.

Interesting description for something that is very simple, yet often a crucial component to the functionality of an engine or generator.

As the majority of you reading this are going to be diesel mechanics or parts shops, you would already understand how flywheels for diesel engines work and how they are to be installed on the engine.

There are plenty of things that you may not know about your flywheel needs when it comes to having to order a replacement; casting number, ring gear part number, clutch size, mounting holes.

A company with salesmen who have the knowledge needed to help find out what your exact needs come in handy.

Did you know that some flywheels are designed to accommodate various size clutches?

There are flywheels with multiple drill patterns so a customer may switch the size of their clutch, depending on vehicle usage and needs.

Would you know the difference between a ‘dual-mass flywheel’ & ‘single mass flywheel’?

A dual mass flywheel is a flywheel in 2 concentric parts or 2 facing flywheels stuck together with a flexible compound to damp down transmitted vibration and gear rattle.

Many trucks that come with dual-mass flywheels can be converted to single mass flywheels. Some of the benefits of doing so include an increase in acceleration, reduced turbo “lag” with turbocharged engines, and increased supercharger efficiency.

Also, single mass flywheels can be resurfaced and reused, while a dual mass flywheel cannot. Dual mass flywheels also, cannot withstand a high rate of abuse & may fail sooner under certain driving conditions.

Are you aware of how long your flywheel can last?

Granted, there are a lot of factors that would go into determining an expected lifecycle of flywheels. Engine & transaxle conditions play a key role as well as the driver and driving style, not to mention road conditions.

Over the years, I have had discussions with customers, various mechanics, and different vendors and one common thing that seems to be agreeable is that the average minimum lifecycle is approximately 4 years.

There is some debate on the high end of a flywheels lifecycle, somewhere between 5-6 years.

Regular maintenance of your flywheel can help extend its lifecycle.

This can consist of replacing the ring gear, the bearing, or both. Sometimes the flywheel may need to be resurfaced.

If these items go bad, they can cause damage to the engine, but if caught in time they can be replaced with relatively little trouble & expense.

Resurfacing a flywheel can help extend the lifecycle of the part.

This is done when the surface of the flywheel has scratches/gouges on it that could ultimately affect the performance of the flywheel.

Resurfacing a flywheel consists of shaving metal from the surface of the flywheel until the surface is smooth & level.

There have been many debates on whether flywheels should be resurfaced and how many times it can be done.

Some feel that you should not resurface a flywheel, just scrap it. Others feel that flywheels can be resurfaced up to 4 times during the life of the flywheel.

Knowing your vehicle’s flywheels and how to maintain them will lead to maximizing their full lifecycle.