Ever wonder how diesel soot, also called Particulate Matter or PM, affects your engine’s performance? Ever wonder what components are most vulnerable to soot contamination? Let’s take a look.

Diesel PM output to the atmosphere is now tightly controlled by EPA regulation. As a result of the gradual tightening of the restrictions on PM, the percentage escaping to the atmosphere has been reduced about 90% on diesel trucks since the time the first regulations were instituted. We are now in what is called “Tier 4” of those regulations. There will be more to come, especially in regulating the fine particles that still get through the Diesel Particulate Filter, called DPF, in the exhaust emission controls known as “After treatment”.

As the word “after” is used to describe the newer emission controls, we can see that the soot which is being filtered is still contaminating all of the “before” components upstream of the DPF. These include the Exhaust Gas Regulation (EGR) valve, EGR cooler, the Diesel Oxidation Catalyst (DOC), the exhaust tubing and exhaust manifold connecting to the DPF and the combustion chamber itself. When the soot in the combustion chamber also contaminates the engine oil, the result becomes further damage to the turbocharger bearings. Among the results of all of these are serious and often catastrophic failures of the components, which cause failures in the emission controls and sometimes cause engine shutdown.

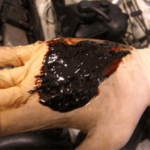

Here’s a view of some examples of soot-related failures:

So, what can we do about the effects of diesel soot to prevent engine failures? There are some measures we can take to protect ourselves to at least reduce the impacts, but we can’t stop them altogether. Here are some suggestions:

- Match the engine oil change frequency to the engine hours and to the engine drive cycle. Those will be subjects of a forthcoming blog. Revert to oil change frequency based on engine hours, not on mileage. This is one of the most critical measures we can take. Contaminated engine oil will cause turbo bearing seizure and a host of other problems, such as clogged oil coolers and stuck or slow hydraulic fuel injectors.

- Use EGR coolers that are designed for high exhaust temperatures and hot/cold extremes in the cooler interior. That means converting to welded stainless steel tubing exhaust channeling, such as now being offered in the Aftermarket. Earlier designs cracked internally and leaked coolant into the entire exhaust system. That results in huge repair bills.

- Maintain constant vigilance over the sensors of DPF differential pressure which senses DPF plugging, EGR valve differential pressures which sense EGR valve sticking, and DPF dosing valve condition, which controls the automatic self-cleaning of the DPF. Also watch for high backpressure codes from contaminated exhaust passages and components. Get after them early because the engine is telling us that it’s getting sick and might die if we don’t take remedial action!

Understanding diesel soot and its effects can lead to actions by which we can help ourselves. Without the above preventive actions, we become the victims of PM contamination and can pay enormous bills on a repetitive basis for as long as we’re operating the vehicle.